Level Measurement

Continuous level measurement and point level detection in liquids and bulk solids

Constant product quality, plant safety and economic efficiency – these are important aspects for any level measuring point.

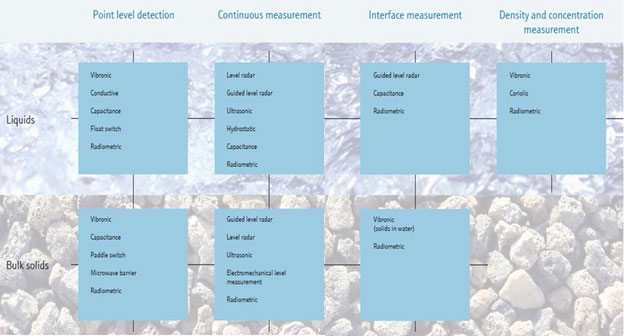

Levels in liquids, pastes, bulk solids or liquefied gases are often measured in tanks, silos or movable containers. For continuous, interface and density measurement as well as for point level detection a broad range of measuring principles is available. Endress+Hauser supports you from planning through commissioning and also maintenance of your measuring point

Benefits

- For every measuring task the right solution

- As world market leader in level measurement, Endress+Hauser guarantees asset protection

- Worldwide support and service

- Know-how for the entire life cycle of your product

Free Space Radar Level Gauge Micropilot NMR81 (Drip-off lens antenna with 80 GHz transmitting frequency for custody transfer applications)

Servo Tank Gauging Instrument Proservo NMS80 (High Precision servo measurement for liquid level, interface and density)

Multihop Modbus I/O Data Radio DX80DR2M-H

Guided radar level measurement

Continuous level measurement in liquids and solids with guided wave radar sensors

Guided radar level measurement with top-down installation of a Levelflex sensor offers perfect application fit in all industries. Guided radar with simple commissioning, trouble-free operation saves time and money. For usage in a wide range of applications – be it in simple storage tanks, in corrosive or aggressive media or heavy duty applications. Check out the broad range of Levelflex devices for guided wave radar applications and click on the button below.

Guided radar level measurement is well suited to liquids and bulk solids. The surface condition of the medium is of minor importance due to the safe guidance of the reflected waves. Turbulent liquid surfaces or foam formation as well as different angled surfaces or outflow funnels, as the occur in bulk solids, do not influence the measurement. Guided radar is also the first choice for interface measurement.

Guided radar measurement: Measuring Principle

Levelflex works with high-frequency radar pulses which are emitted and guided along the probe. As the pulse meets the medium surface, part of the emitted pulse is reflected due to a change of the dc value (relative dielectric constant). The Time-of-Flight between pulse launching and receiving is measured and analyzed by the instrument and constitutes a direct measure for the distance between the process connection and the product surface

Benefits

- Reliable measurement: Unaffected by medium surfaces and tank obstacles or baffles

- Additional measuring safety through End-of-Probe (EoP) evaluation

- Safe measurement also during filling

Servo level measurement

Continuous liquid level measurement in custody transfer and inventory control applications

Servo tank gauging instruments offer high precision measurement for liquid level, interface and density applications. The devices fulfill the exact demands of tank inventory management and loss control and are optimized in regards of total cost saving and safe operation. Check out the broad range of Proservo devices for servo level applications and click on the button below.

Servo level devices as tank gauging instruments are used for custody transfer and inventory control applications with NMi- and PTB-approvals and meet the requirements according to OIML R85 and API 3.1B. Proservo is especially suited for high accuracy custody transfer measurement in crude oil, gasoline, diesel, petrochemicals and chemicals.

Servo level measurement: Measuring Principle

A small displacer is accurately positioned in a liquid medium using a servo motor. The displacer is then suspended on a measuring wire which is wound onto a finely grooved drum housing. When the displacer is lowered and touches a liquid, the weight of the displacer is reduced by liquid buoyancy force. As a result, torque in the magnetic coupling changes, which is measured by 5 sets of Hall sensors.

Benefits

- Unaffected by medium properties like conductivity or dielectric constant

- Custody transfer applications

Vibronic point level detection

Point level switches in liquids and solids

Vibronic point level detection offers safe overfill prevention in liquids and bulk solids in every industry. The second line of defense guarantees the highest degree of safety and availability of the switches. Liquiphant stands for reliable switching unaffected by: changing media properties, turbulences, foam, vibrations or build-up. In silos containing fine-grained or powdery solids Soliphant is the perfect match. For more information click on the button below.

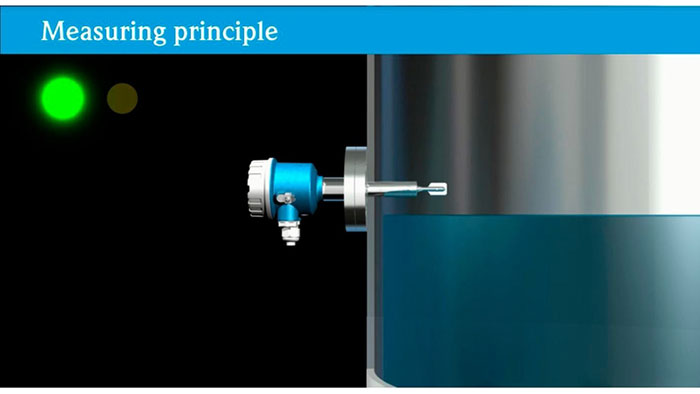

Vibronic point level detection: Measuring Principle

For point level detection in liquids a sensor in form of a tuning fork is excited at its resonant frequency. The drive works piezoelectrically. The oscillating frequency changes as the fork enters the medium. The change is analyzed and translated into a switching signal.

In solids a one-rod sensor is excited at its resonant frequency. The drive works piezoelectrically. The amplitude changes as the fork enters the medium. The change is also analyzed and translated into a switching signal.

Benefits

- Unaffected by media

- Unaffected by media properties

- Easy installation and ready for use without calibration

- Self-monitoring

- No wear and tear, maintenance-free

Radar level measurement

Continuous level measurement in liquids and solids with free space radar sensors

Radar level measurement with top-down installation of a Micropilot sensor offers perfect application fit in all industries. Non-contact radar with simple commissioning, trouble-free operation saves time and money. For usage in a wide range of applications – be it in simple storage tanks, in corrosive or aggressive media or high accuracy tank gauging applications.

Radar measurement: Measuring Principle

Micropilot works with high-frequency radar pulses which are emitted by an antenna and reflected from the medium surface due to a change of the dc value (relative dielectric constant). The Time-of-Flight of the reflected radar pulse is directly proportional to the distance traveled. If the tank geometry is known, the level can be calculated from this variable.

Benefits

- Non-contact, maintenance-free measurement

- Unaffected by medium properties like density and conductivity, in bulk solids also unaffected by filling noise and dust

- Freely adjustable measuring range

- For high temperatures up to +450°C/+842°F

Ultrasonic level measurement

Continuous level measurement in liquids and solids with ultrasonic level sensors

Ultrasonic level measurement with Prosonic sensors provides continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges and powdery to coarse bulk materials. The measurement is unaffected by dielectric constant, density or humidity and also unaffected by build-up due to the self-cleaning effect of the sensors.

The ultrasonic method is a proved, as well as cost-effective solution for level measurement in liquids and bulk solids. Instruments are available as compact or separate versions. This measuring principle is characterized by easy planning and assembly, fast and safe commissioning, a long service life and reduced maintenance costs. Typical applications include abrasive and aggressive media, even in rough ambient conditions.

Ultrasonic measurement: Measuring Principle

Prosonic is based on the Time-of-Flight principle. A sensor emits ultrasonic pulses, the surface of the media reflects the signal and the sensor detects it again. The Time-of-Flight of the reflected ultrasonic signal is directly proportional to the distance traveled. With the known tank geometry the level can be calculated.

Benefits

- Non-contact, maintenance-free measurement

- Measurement unaffected by media properties, like dc value or density

- Calibration without filling or discharging

- Self-cleaning effect due to vibrating sensor diaphragm