Liquid Analysis

Comprehensive product range for all analytical parameters

Environmental protection, consistent product quality, process optimization and safety – just a few reasons why liquid analysis is becoming increasingly essential. Liquids such as water, beverages, dairy products, chemicals and pharmaceuticals have to be analyzed day in and day out. We support you in fulfilling all these measuring tasks with application know-how and cutting-edge technologies. Discover our comprehensive portfolio and choose the product best suited to your process needs.

Benefits

- From standard sensors to complete measuring stations – we provide cutting-edge technology for every liquid analysis parameter.

- Our high-precision instruments help you to increase product yield, improve product quality and ensure process safety.

- State-of-the-art communication interfaces and protocols enable you to seamlessly integrate our devices into your processes and plant asset management.

- Whether process lab, process or utilities – use our know-how and expertise to optimize your application.

- As leading supplier of analytical measuring technology, we support you during the entire product life cycle – everywhere in the world.

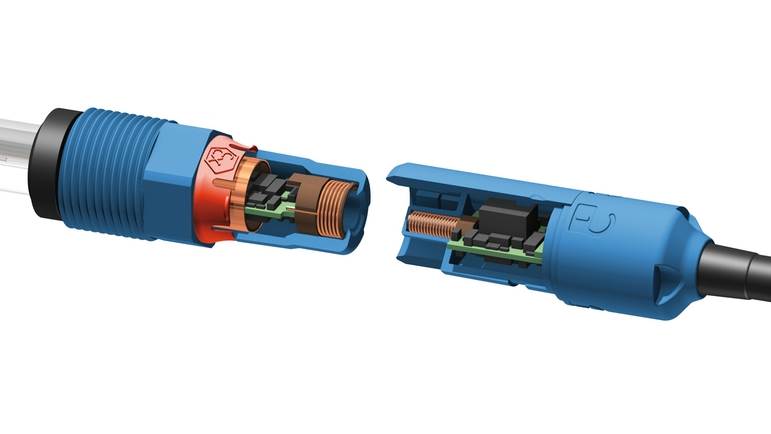

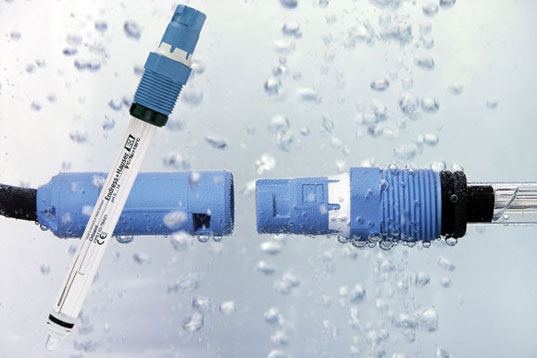

Memosens 2.0: Cutting-edge sensor technology reloaded

Make life easier, increase process safety and stay connected with Memosens 2.0 digital technology

Memosens technology has revolutionized liquid analysis technology. It converts the measured value to a digital signal and transfers it inductively to the transmitter, eliminating the problems associated with moisture. With signal alarms in the event of transmission disruption, Memosens offers safe data transfer for increased availability of the measuring point and trouble-free processes. With Memosens 2.0, measuring points become completely future-proof and ready for IIoT.

Disinfection and chlorine sensors and transmitters

Systematic disinfection is an essential step in water treatment and legally required in many areas to protect people and systems. However, high doses of disinfectants can be toxic. Our sensors for free chlorine, total chlorine and monitor drinking water, process and reuse water, pool water or seawater to ensure regulation-compliant disinfection.

Free chlorine is the most important disinfectant in water treatment due to its easy handling and strong disinfecting effect. Free chlorine sensors are applied in:

- Drinking water – to ensure sufficient disinfection

- Food – to provide hygienic bottling and packaging

- Pool water – to dose disinfectant efficiently

Total chlorine is a good indicator of residual disinfectants in discharge water. The sensors are used in WWTPs:

- To measure the effluent water’s disinfection status.

- To control reuse of water

Benefits

- With us you get the full range of instruments for water disinfection monitoring: free chlorine sensors and total chlorine sensors with matching transmitters and accessories.

- Our chlorine sensors and transmitters and meet all requirements from basic functionality up to multichannel and multiparameter measurement.

- To provide you with full flexibility, our chlorine probes are designed both for use in channels and basins as well as for installation in flow assemblies.

- Check out our ready-to-use disinfection monitoring panels . They come fully equipped with sensor, transmitter, assembly, filter, check valve, sampling tab, etc. and provide you with a complete and compact measuring point.

Digital total chlorine sensor

Total chlorine is the mixture of free and bound chlorine components and thus a good indicator of residual disinfectants in discharge and process water. Memosens free chlorine sensor provides continuous measurements of total chlorine, even after periods when no chlorine is present. This enables to measure “ zero” chlorine, the absence of chlorine. Thanks to Memosens 2.0 technology, the sensor combines maximum process and data integrity with simple operation. This is the perfect basis for predictive maintenance.

The sensor Memosens CCS53E for total chlorine measures reliably in:

- Wastewater treatment plants: to control the outlet water and enable reuse

- Process water in utilities of all industries: to detect chlorine and avoid any damage, for example in cooling towers

- Food and beverage industry: to ensure hygienic filling and high food quality in washing water and to protect membranes in reverse osmosis systems

- Drinking water: to ensure disinfection and avoid overdosing

- Pool: to detect contaminants

Benefits

- The sensor is not deactivated after periods of time when no chlorine is present, but reacts right away. This continuous measurement facilitates quick responses to process changes and ensures compliance with regulations.

- The low-maintenance, amperometric sensor reduces the cost of ownership of the measuring point, particularly compared to colorimetric measuring systems.

- High process up-time: pre-calibrating the sensor and swaping it with plug & play enables a fast sensor exchange. Plus, the polarization time is faster with Memosens 2.0.

- Easy combination with other relevant parameters of liquid analysis such as pH and ORP by easily connecting the Liquiline multiparameter transmitter.

- Wide measurement range for different applications: From zero to trace measurement up to total chlorine concentrations of 20 mg/l.

Digital free chlorine sensor

Digital free chlorine sensor Memosens ensures precise and consistent disinfection monitoring in drinking water, pool and process water and in utilities. This sensor for determining free chlorine features extremely fast response times even at low water volumes. This guarantees efficient process control and safe processes. Thanks to Memosens 2.0 technology, sensor combines maximum process and data integrity with simple operation. This provides the perfect basis for predictive maintenance and IIoT connectivity.

The free chlorine sensor Memosens is suitable for a wide range of water qualities:

- Drinking water: to secure disinfection

- Utilities: to detect free chlorine and avoid any damage

- Process water: for hygienic and safe packaging and bottling of products in food processing

- Pool water: to dose disinfectant efficiently

Benefits

- The low-maintenance, amperometric sensor reduces the cost of ownership of the measuring point, particularly compared to colorimetric measuring systems.

- Increased process up-time: pre-calibration of the sensor allows for real plug & play and faster polarization time thanks to Memosens 2.0 technology.

- Fast response time (t90 < 25 s) provides an accurate process view and enables prompt reaction to process changes as well as efficient process control.

- High process safety and efficient dosing: precise and long-term stable measurement ensures consistent process monitoring and permits individually adapted disinfectant dosing.

- Suitable sensor versions for every measurement range: From trace measurement up to free chlorine concentrations of 200 mg/l.

- Connection to the Liquiline multiparameter transmitter facilitates easy combination with other parameters of liquid analysis such as pH and ORP.

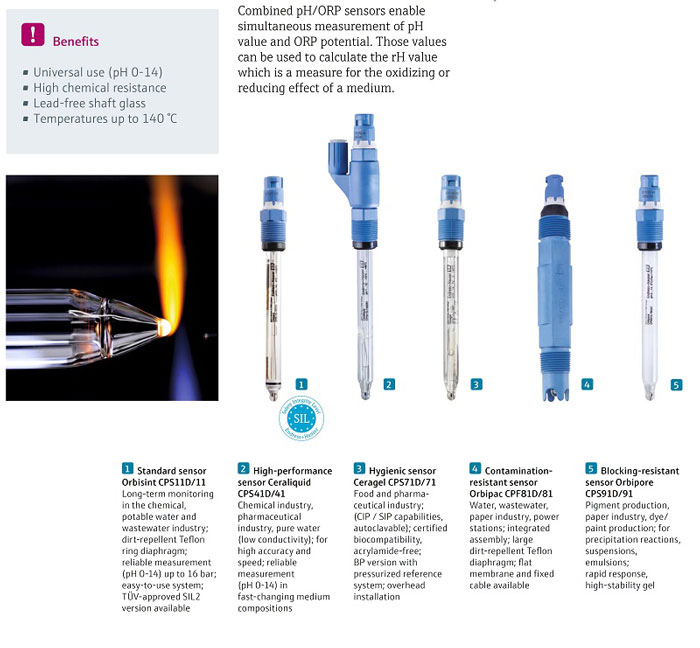

pH sensors and transmitters

pH measurement with glass electrodes and enamel electrodes

The pH value is used as a unit of measurement for the acidity or alkalinity of a liquid medium. The pH-sensitive element of glass electrodes is a glass bulb that supplies an electrochemical potential which is dependent upon the pH value of the medium. This potential is generated because small H+ ions penetrate through the outer layer of the membrane while the larger negatively charged ions remain in the solution.

Glass pH probes contain an integrated Ag/AgCl reference system that serves as the required reference electrode. The pH value is calculated from the potential difference between the reference system and the measuring system using the Nernst equation. Our pH sensors and transmitters achieve outstanding linear measuring performance over an extremely wide pH range!

The measuring principle of enamel pH electrodes corresponds to that of glass pH sensors, however, the pH-sensitive element is enamel.

pH measurement with ISFET electrodes

The pH value is measured with an ion-selective field effect transistor (ISFET). It is a simple transistor with a source and drain that are separated from the base by a semiconductor. Hydrogen ions from the medium may accumulate here. The resulting positive charge on the outside is ‘mirrored’ on the inside of the base where a negative charge occurs. This makes the semiconductor channel conductive. The more H+ ions accumulate on the base, the more current can flow between the source and drain.

Benefits

- Our pH sensors and transmitters meet all requirements from basic functionality up to multichannel and multiparameter measurement.

- We offer pH buffers, pH solutions and pH standards for pH calibration to ultimate precision. They are produced in our own permanent calibration laboratory that has successfully passed the DAkkS accreditation (German accreditation authority).

- The different types of electrodes cover all kinds of diaphragms and reference systems, from dirt-repellent PTFE junctions over highly sensitive ceramic diaphragms to blocking-resistant open apertures.

- We offer pH assemblies for all fields of applications: fixed installation assemblies, immersion assemblies, flow assemblies and retractable assemblies.

- Automated systems for calibration, adjustment and cleaning ensure optimum performance of the pH sensors and transmitters in chemical processes, pharmaceuticals production or hygienic applications.

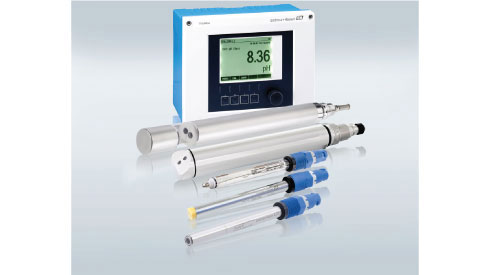

Liquiline: cutting-edge transmitter platformt

Transmitters, analyzers and samplers for future-proof plant design and safe operation

Liquiline is the ideal platform for all liquid analysis applications and forms the basis for our state-of-the-art transmitters, analyzers and samplers. The uniform operation across all products offers convenience and ease of use and protects your process from operating errors. Liquiline’s standardized components optimize your spare part stock and so provide significant cost savings. Better still, our Liquiline products can be easily expanded for full flexibility in the future

Benefits

- Maximum plant safety provided by one-of-a-kind, condensate-proof Contite measuring cell

- Contite cell offers very good reproducibility and long-term stability even after temperature shocks

- The ceramic cell has extremely good chemical compatibility and high mechanical stability thanks to ultra-pure 99.9% ceramic

- Robust ceramic membrane with integrated membrane breakage detection – also suitable for vacuum applications

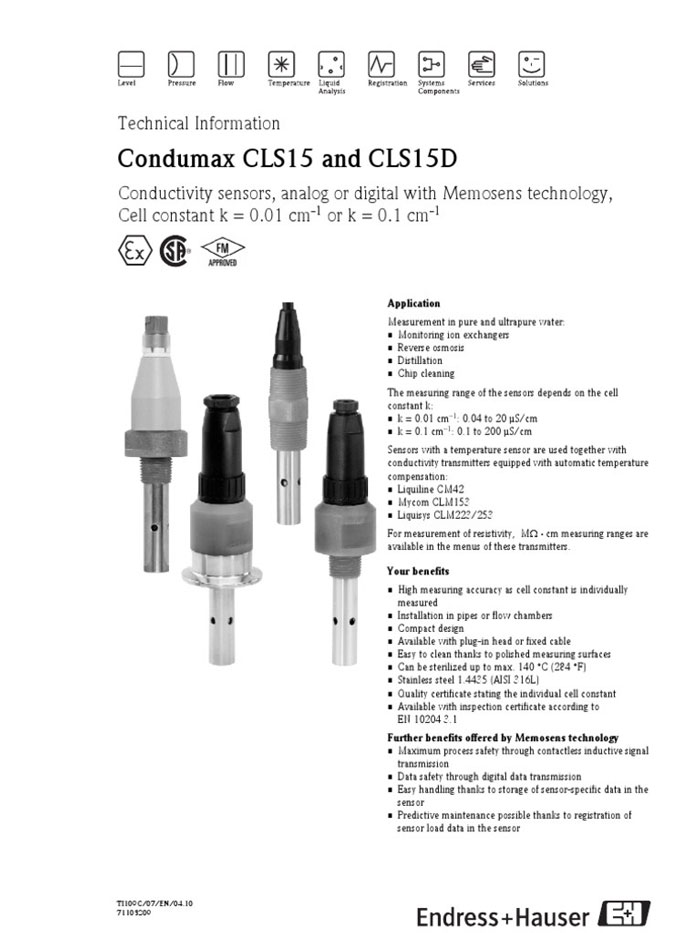

Conductivity sensors and transmitters

Products for high precision conductivity measurement in all industries

In many applications conductivity is crucial for process control, product monitoring, water monitoring, or leakage detection. We provide reliable and accurate instruments for all measurement ranges and conditions, such as ultrapure water, CIP cycles, hazardous areas or hygienic processes

Benefits

- We offer helpful conductivity calibration solutions and conductivity calibration standards for accurate measurements.

- The exact cell constant of the conductivity sensors is factory-measured and certified.

- Our portfolio of conductivity sensors and transmitters covers all conductivity measuring ranges and all commonly used process connections.

- Compact devices consisting of conductivity sensor and transmitter are perfectly suitable for the food & beverage industry.